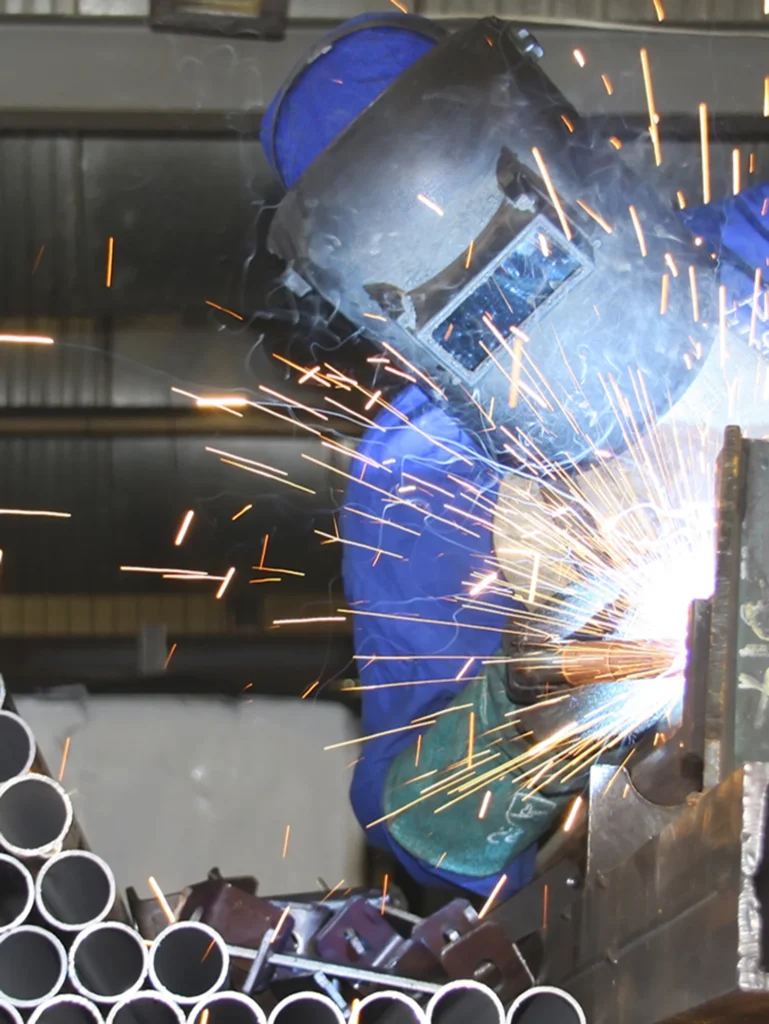

Coded Tig Welding

Coded Welding

Precision and Excellence in Multi-Coded Welding Solutions

At Kennedy Engineering, we specialise in multi-coded welding for our fabrication projects, ensuring the highest standards of quality and safety. Our team of skilled welders are certified and coded for a variety of welding techniques and materials, allowing us to meet the diverse needs of our clients across multiple industries.

We are proud to be coded for the following types of welds:

Coded Stainless Steel Welding

Our welders are certified to work with various grades of stainless steel, including austenitic, ferritic, and duplex stainless steels. This expertise is crucial for projects requiring corrosion resistance and high-temperature performance.

Carbon Steel Welding

We have extensive experience in carbon steel welding, which is essential for structural applications, pipelines, and general fabrication work. Our coded welders are proficient in various techniques suitable for different carbon steel grades.

Dissimilar Metals Welding

Our team is skilled in the complex process of joining dissimilar metals, such as stainless steel to carbon steel or aluminium to steel. This specialised capability is vital for projects that require the properties of different metals in a single structure.

wELDING techniques

Our coded welders are certified in multiple welding processes, including:

MIG (Metal Inert Gas) welding

TIG (Tungsten Inert Gas) welding

Stick (SMAW) welding

Flux-cored arc welding (FCAW)

Quality Assurance

All our coded welding is rigorously tested and approved by British Engineering Services, one of the UKs’ leading independent testing, inspection, and certification bodies. This ensures that our welds meet or exceed the required British and international standards, including BS EN ISO 9609-1 for steel welding and BS EN ISO 9606-2 for aluminium welding.

Our commitment to quality extends beyond certification. We regularly conduct in-house testing, including visual inspections, dye penetrant testing, and radiographic examinations, to maintain the highest standards of weld integrity.

Contact us

Contact Us for Engineering Solutions

Armagh

- 75 Seagahan Road, Armagh BT60 2BJ

- 07796 710309

- kennedy-engineering@hotmail.co.uk